Industrial automation and robotics are no longer futuristic ideas—they are a core part of global competitiveness across manufacturing, healthcare, transportation, agriculture, and beyond. These technologies drive efficiency, safety, and sustainability while reshaping industries at an unprecedented pace.

For researchers, graduate students, and faculty, staying ahead of these trends is essential to meaningfully contribute to both academia and industry. This blog highlights the top industrial automation and robotics trends for 2025, along with recent breakthroughs and research opportunities.

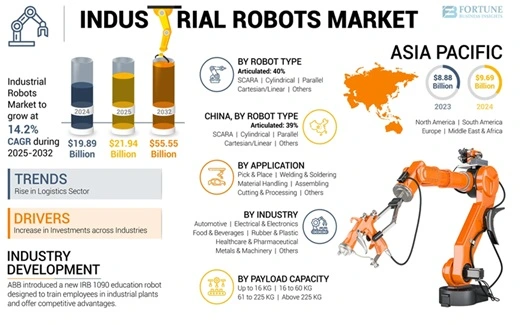

Source: https://www.fortunebusinessinsights.com/industry-reports/industrial-robots-market-100360

Artificial Intelligence and Machine Learning are increasingly embedded into industrial systems, enabling machines to learn from data and make autonomous decisions.

Graduate students can explore:

Industry 4.0 combines IoT, big data, and cloud computing to enable intelligent, interconnected factories. These systems allow real-time monitoring, optimization, and decision-making.

Cobots are designed to work safely alongside humans, unlike traditional robots confined to safety cages. They are widely used in assembly, packaging, and inspection, especially in SMEs.

IIoT connects equipment, sensors, and machines to create smarter, data-driven production environments. It is the foundation of predictive maintenance and real-time analytics.

Sustainability is shaping the future of automation. Energy-efficient robots, waste reduction, and eco-friendly technologies are gaining traction.

Soft robotics uses flexible, elastic materials to handle delicate items and adapt to uncertain environments, with applications in healthcare, food handling, and agriculture.

AR is transforming how workers interact with machines by providing real-time overlays and training tools.

Combining edge and cloud computing enables faster, real-time decision-making while offering scalability and flexibility.

Automation is creating demand for a skilled workforce. Academic institutions and industries are collaborating to bridge this gap.

The future of industrial automation and robotics in 2025 is driven by AI, IIoT, cobots, sustainable robotics, and digital transformation. For students, researchers, and professionals, exploring these domains offers exciting opportunities to innovate and contribute to shaping the next industrial revolution. By combining technical skills with forward-thinking research, you can play a key role in building smarter, greener, and more connected industries.

Q1: What are the top robotics trends in 2025?

Ans.: AI-powered robots, cobots, IIoT integration, and sustainable automation are among the leading trends.

Q2: What are the best areas for a Master’s thesis in robotics and automation?

Ans.: Areas include Human-Robot Interaction (HRI), AI for predictive maintenance, and soft robotics for healthcare applications.

Q3: Do cobots replace human jobs?

Ans.: No. Cobots complement human workers by handling repetitive or hazardous tasks, allowing humans to focus on more complex roles.

Q4: Which programming languages are essential for robotics research?

Ans.: Python (AI/ML applications), C++/ROS (real-time robotics), and MATLAB/Simulink (simulation and modeling) are essential.

Q5: Where can I find open-source robotics simulation tools and datasets?

Ans.: You can find them at OpenAI Gym (reinforcement learning), Gazebo/ROS (robot simulation), and Kaggle (AI/ML datasets).

Q6: What industries benefit the most from industrial automation and robotics?

Ans.: Manufacturing, automotive, electronics, healthcare, logistics, and agriculture are leading adopters, with growing use cases in pharmaceuticals, energy, and food processing.

Q7: What are the challenges in implementing Industry 4.0?

Ans.: Key challenges include high setup costs, cybersecurity risks, data privacy concerns, workforce skill gaps, and integrating legacy systems with modern smart technologies.

Q8: What is the difference between traditional robots and cobots?

Ans.: Traditional robots are typically caged and operate independently, while cobots are designed to safely collaborate with humans, making them ideal for flexible, small-scale production.

Q9: How is AI transforming industrial robotics?

Ans.: AI enables robots to analyze data, adapt to changing conditions, perform predictive maintenance, recognize patterns, and operate with higher autonomy and precision.

Q10: What is the role of IIoT in predictive maintenance?

Ans.: IIoT sensors collect real-time machine data, which is then analyzed using AI/ML models to predict failures before they occur, reducing downtime and saving costs.

Q11: What skills are in demand for careers in industrial automation?

Ans.: Skills in robotics programming (Python, C++, ROS), AI/ML, data analytics, IoT integration, cybersecurity, and knowledge of industrial protocols are highly sought after.

Q12: What are examples of green robotics applications?

Ans.: Energy-efficient robots in automotive manufacturing, solar-powered agricultural robots, and automation systems that reduce waste through additive manufacturing and recycling.

Q13: Are soft robots safe for human interaction?

Ans.: Yes. Soft robots are built using flexible materials, making them ideal for delicate applications like surgery, rehabilitation, food handling, and collaborative tasks with humans.

Q14: What is the future outlook for robotics research?

Ans.: The future will see increased focus on human-robot collaboration, AI-powered autonomy, sustainable robotics, and cross-disciplinary applications in medicine, agriculture, and smart cities.

Explore more resources to deepen your knowledge in automation and robotics research:

|

Citation Indices

|

All

|

Since 2020

|

Citation |

2359 |

1680 |

h-index |

19 |

15 |

i10-index |

57 |

24 |

|

Acceptance Rate (By Year)

|

|

|

Year

|

Percentage

|

|

2023

|

9.64%

|

|

2027

|

17.64%

|

|

2022

|

13.14%

|

|

2021

|

14.26%

|

|

2020

|

11.8%

|

|

2019

|

16.3%

|

|

2018

|

18.65%

|

|

2017

|

15.9%

|

|

2016

|

20.9%

|

|

2015

|

22.5%

|